The library laptop checkout program was started with Student Tech Fee money back in 2010. Since then the program has grown from 10 clunky old Dell laptops to 15 slick new Surface Pros and 8 MacBook Airs and I can say that in its current configuration it has been wildly popular.

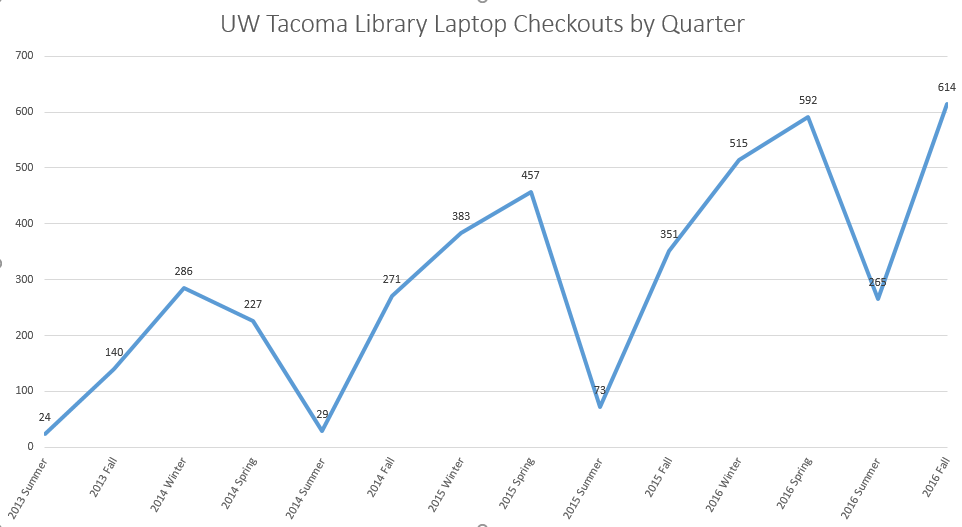

The Library started collecting stats on laptop checkouts in Summer of 2013. That quarter the library only checked out a laptop 24 times. That makes sense to me because they were old, slow, and heavy. They were still somewhat popular because people needed laptops. And as recent as Spring 2015, the Library was checking out laptops 457 times a quarter.

That all changed last summer when the STFC (student tech fee committee) funded 15 new Surface Pros and 5 new MacBook airs.

The first quarter that we had modern computers for checkout, the number of checkouts went up by 80 over the same period the year before.

The second quarter, as word of mouth spread, checkouts increased by 132 for the quarter. And by Spring of 2016, that number went up to 592 checkouts. for the quarter. An increase of 136 over the same period in the year before.

So, the library went back to the students and asked for 3 more laptops. And this fall, the library checked out laptops 614 times. 343 more times than we had with the older laptops and 263 ,more times than in the previous fall.

This partnership has been a great success for the students at UW Tacoma. And a huge thank you to the students for funding this program is in order. As well a huge thank you to the circulation staff at the Library who have the thankless task of checking out all these laptops along with a rather onerous inspection process.

Despite some setbacks you can bet that the Library will be asking for more laptops from this next round of Student Tech Fee proposals.

(Graphic showing increase in laptop use over 3 years from 140 checkouts in Fall 2013 to 614 checkouts in Fall 2016.)