The planetary (epicyclic) geared unicycle hub is a transmission designed specifically for a unicycle. The goal is to gear up the wheel revolution to crank revolution ratio. In this case, that ratio is 1.5:1. That is, for every revolution of the pedal cranks, the wheel will make 1.5 revolutions.

For my prototype unicycle, I had a 24" wheel built. With the hub gear ratio the effective diameter of the wheel was 36". I chose the 1.5:1 gear ratio because it makes a very common unicycle wheel size (24") appear to ride like a 36" wheel, another size with which many unicyclists are now familiar. This similarity is in speed and cranking effort only. It does not reproduce the comfort and esthetic advantages of having a large diameter, pneumatic tire to smooth out bumps and road irregularities and look cool.

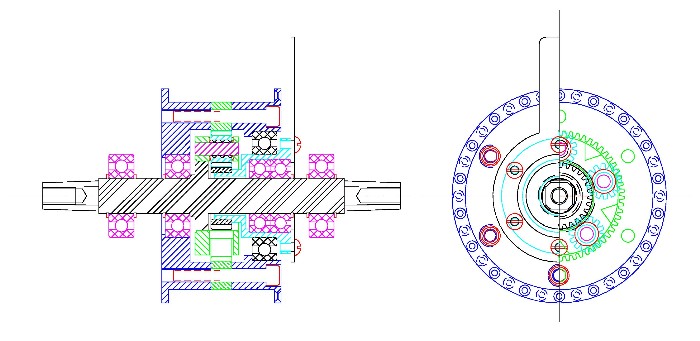

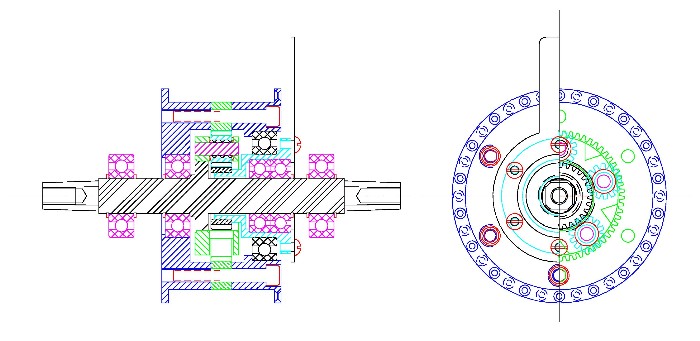

I live in Seattle which is about an hour away from the site in the Snoqualmie Valley where both the NAUCC-2002 and UNICON-11 conventions were held in the summer of 2002. I had a geared prototype unicycle available for anyone to ride there. I had a variety of seatposts with saddles mounted for people of various sizes. It was an ideal place to have people from all over the world who have ridden both a 24" and 36" wheel test this geared prototype. I had a second hub partially assembled as a visual aid and also a set of D-size drawings showing each part and its dimensions and a cross-sectional view of the assembly. These drawings (*.jpeg versions) are already posted here on my web site.

A number of unicycle gearing schemes have been tried in the past. These include chain driven models, outside gear driven models, and modified Sturmey-Archer hubs. In fact, the Sturmey-Archer web site provides a good overview of the operation of planetary gear systems. All of these approaches had some drawback. The chain driven systems suffered from backlash due to the inherently slack nature of chain drive. Outside gear sytems required odd and necessarily shaky locations for split crank assemblies in which two short cranks must be attached, one to each side, of the fork. The modified Sturmey-Archer hubs were cluges of parts designed for another function altogether being forced by welding, filing, bending, and machining to become geared unicycle hubs.

Having already heard of these designs and their drawbacks I decided to design, from the ground up, an internally geared hub based on the epicyclic principle (again, Sturmey-Archer and automotive transmissions) specifically for a unicycle in order to avoid the pitfalls of the other methods. In this design there are a few important requirements to meet. The drive component

must be integral with the unicycle axle so that the axle may go all of the way through the hub for strength. The gear ratio must be greater than one (the difficult one in this case) because the goal is speed. The hub must be as compact as possible. Any gears or bearings used must be stock items that are available off the shelf and reasonably priced. Naturally, all of these requirements conflict and the finished product is to some

extent a compromise.

Above is the final design pass for the epicyclic hub. The gear ratio is 1.5 to 1. The gears are commercially available and very stout. The ring gear is the pricey one at about $55. I bought the gears to make 2 units for $194 total or $97 per unit. I bought the bearings for $144 total or $72 per unit. The tab that you see is screwed to the sun gear assembly and attaches to the fork. One of the technical problems that concerned me was the torque applied to the frame by the sun gear assembly which must remain stationary around the axle. I thought this would tend to push the seat in the direction pedaled making it essential for the rider to keep his or her weight on the seat. Since it is attached to only one side of the fork it should also have applied a slight torque around the seatpost axis tending to make the seat rotate as the rider pedals. As it turned out, these effects were insignificant enough to be unnoticeable.